Welcome to blogrouters.com, where we dive into groundbreaking innovations shaping the tech world. Have you ever wondered how companies like Intel and NVIDIA get their cutting-edge technology? Enter ASML, a global leader in advanced manufacturing. In this blog, we explore how ASML makes 3D printers for Intel and NVIDIA, transforming production and setting new benchmarks in technology. This fascinating process combines precision, innovation, and collaboration, paving the way for a smarter future.

Let’s uncover how ASML is revolutionizing the tech world with its 3D printing marvels and why this technology is a game-changer.

What is ASML, and Why Does It Matter?

ASML is a Dutch multinational corporation specializing in advanced semiconductor manufacturing. Their focus is on creating machines for chipmakers, and their 3D printing technology has taken the industry by storm.

- Precision and Innovation: ASML uses extreme ultraviolet lithography (EUV), a technology that ensures chips are smaller and faster.

- Tech Giants’ Partner: asml makes 3d printers for intel and nvidia rely heavily on ASML for cutting-edge tools. This partnership drives breakthroughs in artificial intelligence, gaming, and computing.

- Why It’s Unique: ASML’s 3D printers combine ultra-precise mechanics and advanced software, making them indispensable for chip manufacturing.

By leveraging ASML’s machines, Intel and NVIDIA can innovate faster, maintaining their dominance in the tech landscape.

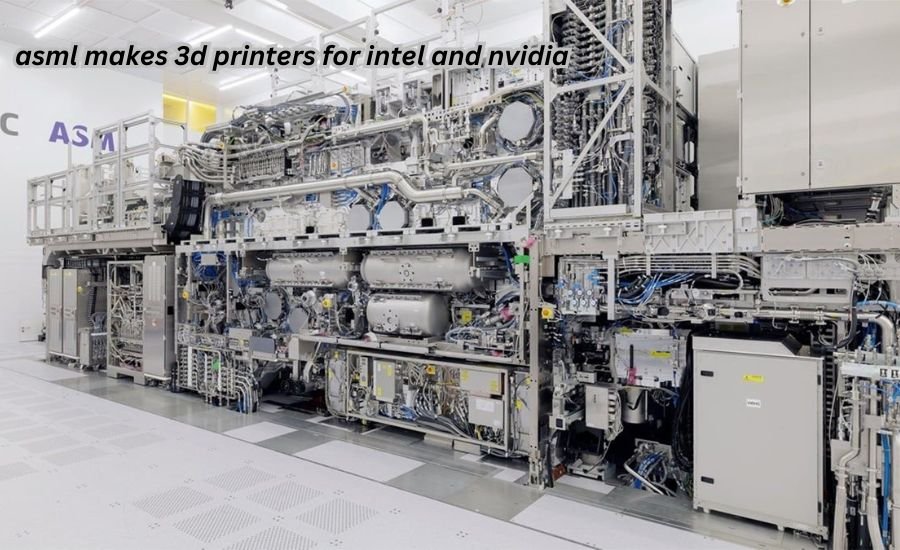

How ASML Makes 3D Printers for Intel and NVIDIA

ASML’s process is both complex and fascinating, involving advanced technologies and a meticulous approach.

Advanced Design

Each 3D printer starts with a customized design tailored to meet Intel’s and NVIDIA’s specific needs. ASML engineers collaborate closely with their clients to ensure every requirement is met.

- Laser Precision: ASML uses laser-guided systems for unrivaled accuracy.

- Client Collaboration: Frequent feedback loops ensure the printers match the unique demands of both Intel and NVIDIA.

Manufacturing Process

The production involves layer-by-layer assembly using state-of-the-art robotics and materials.

- Materials Used: ASML employs high-grade metals and polymers to ensure durability.

- Automation: Robotic arms and AI-powered systems streamline the process, reducing errors.

Quality Assurance

Before delivery, ASML’s 3D printers undergo rigorous testing to ensure they meet the highest standards.

- Stress Testing: Machines are pushed to their limits to guarantee reliability.

- Certification: Only after passing numerous tests are the printers shipped to Intel and NVIDIA.

- Read More : CNH Mass Layoff Wisconsin

Benefits of ASML’s 3D Printers for Tech Giants

The advantages of ASML’s technology are transformative for companies like Intel and NVIDIA.

Faster Production

With ASML’s 3D printers, chip production is faster than ever, allowing tech companies to keep up with growing demand.

- Reduced Downtime: Automated systems minimize delays in manufacturing.

- Higher Output: More chips are produced in less time, boosting efficiency.

Cost-Effective Solutions

Though the initial investment is significant, the long-term cost savings are substantial.

- Reduced Waste: Precision manufacturing reduces material wastage.

- Energy Efficiency: These printers consume less power, cutting operational costs.

Innovation Boost

ASML’s machines empower Intel and NVIDIA to develop next-generation chips, leading to advancements in AI, gaming, and computing.

How ASML’s 3D Printing Technology Impacts the Industry

The ripple effects of ASML’s innovation extend far beyond its direct clients.

Global Semiconductor Growth

ASML’s technology accelerates global chip production, vital for industries like healthcare, automotive, and telecommunications.

- Smarter Devices: Faster chips mean smarter, more efficient devices for consumers.

- Economic Growth: Increased production drives economic development worldwide.

Environmental Impact

ASML focuses on sustainable manufacturing, minimizing its ecological footprint.

- Green Manufacturing: Energy-efficient systems reduce carbon emissions.

- Recyclable Materials: Many components are designed to be recycled, reducing waste.

The Future of ASML, Intel, and NVIDIA Collaboration

The partnership between ASML, Intel, and NVIDIA is set to redefine the tech industry.

- Emerging Technologies: Expect advancements in quantum computing and AI-driven systems.

- Market Leadership: With ASML’s help, Intel and NVIDIA will likely maintain their dominance in the semiconductor market.

ASML’s relentless innovation ensures it will remain a key player in the tech world for years to come.

Conclusion

In summary, ASML’s 3D printing technology is a cornerstone of modern semiconductor manufacturing, driving innovation for giants like Intel and NVIDIA. This collaboration not only enhances chip production but also sets the stage for groundbreaking technological advancements.

The ripple effects of this partnership are transformative, influencing industries worldwide and promising a future brimming with possibilities. As ASML continues to innovate, the tech world can expect even greater achievements ahead. Stay tuned to blogrouters.com for the latest updates on groundbreaking technologies!

FAQs

Q: What is ASML’s primary focus?

A: ASML specializes in creating advanced machines for semiconductor manufacturing, including 3D printers for Intel and NVIDIA.

Q: How does ASML’s 3D printing technology work?

A: It involves precision-guided manufacturing, advanced materials, and automation to produce high-quality semiconductors.

Q: Why is ASML important for Intel and NVIDIA?

A: ASML’s technology enables these companies to innovate faster and produce better chips.

Q: Is ASML’s 3D printing environmentally friendly?

A: Yes, ASML uses energy-efficient systems and recyclable materials to minimize its environmental impact.

Q: What industries benefit from ASML’s technology?

A: Healthcare, automotive, telecommunications, and consumer electronics are just a few sectors that benefit from ASML’s innovations.